Description

CONiX HiL Solution

Hardware-in-the-Loop Solution CONiX HiL

Discover the precise hardware and modular software solutions from b-plus for your AD HiL and ADAS HiL applications. Our compact HiL testing tools enable efficient error detection and correction directly at the developer’s table. Enjoy flexibility through scalable solutions – from simple tools to fully equipped HiL rack systems for 24/7 operation. Increase your efficiency in the hardware-in-the-loop test environment with the know-how of a data specialist.

Integrated hardware and software solutions

Benefits

Highest scalability

![]()

We offer open-loop and closed-loop processes that support all phases of development. The complex systemcan be split down to modular, self-contained and simple single modules. The combination and integration of the modules will be adapted according to the customer’s workflow:

- b-HiL for realtime injection directly at the test table

- CONiX HiL Solution as HiL integrator

- CONiX HiL Solution XXL as HiL rack system

High performance hardware

- Time-synchronous playback of raw sensor data, vehicle BUS and network information

- Out-of-the-box inject hardware

- Supports common sensor technologies (radar, lidar, and camera)

- Raw data interfaces: CSI-2, GMSL2, FPD-Link III

- 24/7 operation even for extremely high bandwidths

- Suitable for high-performance AD platforms

Reliable software

- Reliability through existing and tested software modules

- Flexibility through seamless integration into your environment

- Highly qualified engineering and more than 20 years of project experience

Expert Teams

- Reduction of project escalation and validation costs

- Quality through highly qualified engineering

- Self-diagnosis of the HiL system

- Time savings due to perfected technology right from the start

Our products and complete solutions

Base system

- Solution ideal for the developer workspace

- Early access to hardware in the loop/re-injection of sensor data to enable improved early software reliability

- Flexible setup for clustering multiple sensor data streams

- Time-correlated injection of recorded raw sensor data and bus data for reproducible real test drives

- Offers a complete development environment for integration and HiL testing in a compact 19” rack

- Powerful hardware

- Integrated raw data interface, network playback, power on/off relay, 3rd party hardware/software integration as well as hardware/software integrations and a replay option

- Easy integration into your CI/CD infrastructure

- Configurable workflows and sequences for optimal usability

- Flexibility to adapt functionality to ECU characteristics or cloud/data center platforms

- A range of protocol stacks, importers and converters can be added as required: e.g. XCP and DoIP/UDS stacks for maximum flexibility, also MDF4 reader/writer for compatibility

- The CONiX HiL Rack System offers all the benefits of our HiL Integrator, scaled in a 19” rack for fully automated replay

- Reduces user maintenance and system downtime

- Provides 24/7 systems with high data rate performance

- Highest scalability by combining individual rack trays with power supplies and high-end network switches in 19″ racks

- Optional packages, such as a Replay Manager for client orchestration or an Service-Level-Agreement, are available at any time

- Best choice for sensor or ECU validation applications

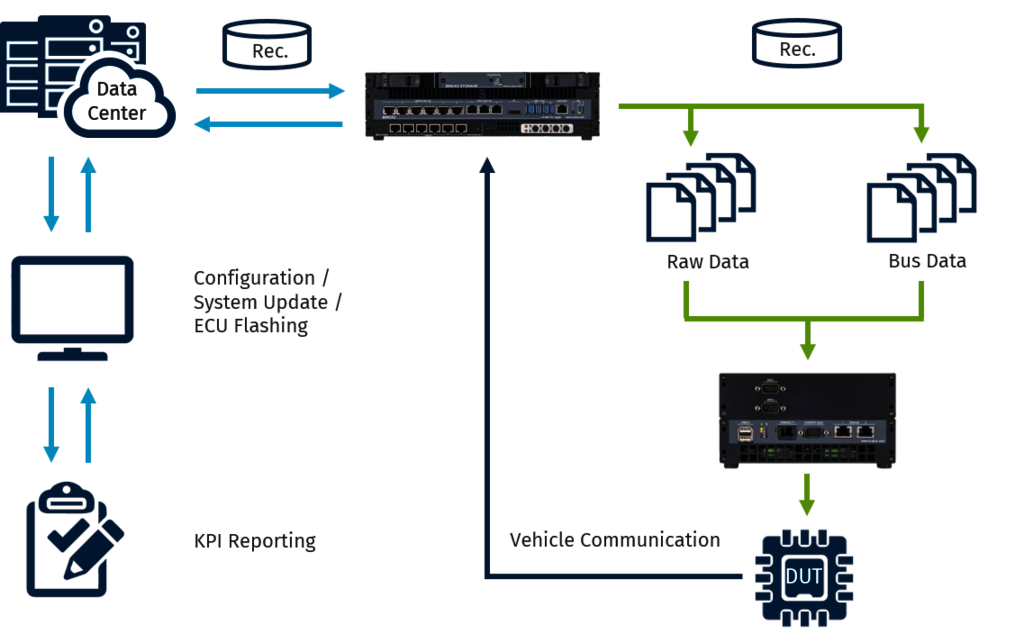

Open loop process with data center connection

The perfect HiL package for your project

Use cases

- Open loop on recording basis

- Technologies used: CAN & CSI-2

- Engineering: Continuous integration, MDF support, integration into development

- in development environment, Failure Injection

- Building Blocks: Raw Data Replay, Network Replay

- Closed loop on simulation basis

- Technologies used: CAN, SOMEIP & GMSL

- Engineering: Project planning, system architecture, system integration

- Building Blocks: HiL Sequencer, Test Reporter

- Open loop on recording basis

- Technologies used: SOMEIP & GMSL

- Engineering: Project planning, KPI determination,

- Building Blocks: HiL Sequencer, MDF Lib, Cloud Connector